Induction heating is a highly efficient, fast, and precise method for heating conductive materials in various industries. Unlike traditional heating methods, induction heating uses electromagnetic fields to generate heat directly within the material, offering numerous advantages in manufacturing and processing applications. This guide explores the principles, benefits, applications, and future of induction heating technology. Look for the best info about induction heating.

Induction heating is a process that heats electrically conductive materials using electromagnetic induction. This technology is widely used across industries for applications that require rapid, precise, and efficient heating. From melting metals to cooking food, induction heating has revolutionized the way we approach heat processing tasks.

The ability to heat materials quickly and precisely has made induction heating an invaluable tool in industries ranging from automotive manufacturing to culinary arts. Its efficiency and environmental benefits contribute to its growing popularity and adoption in various sectors.

How Induction Heating Works

Basic Principles of Electromagnetic Induction

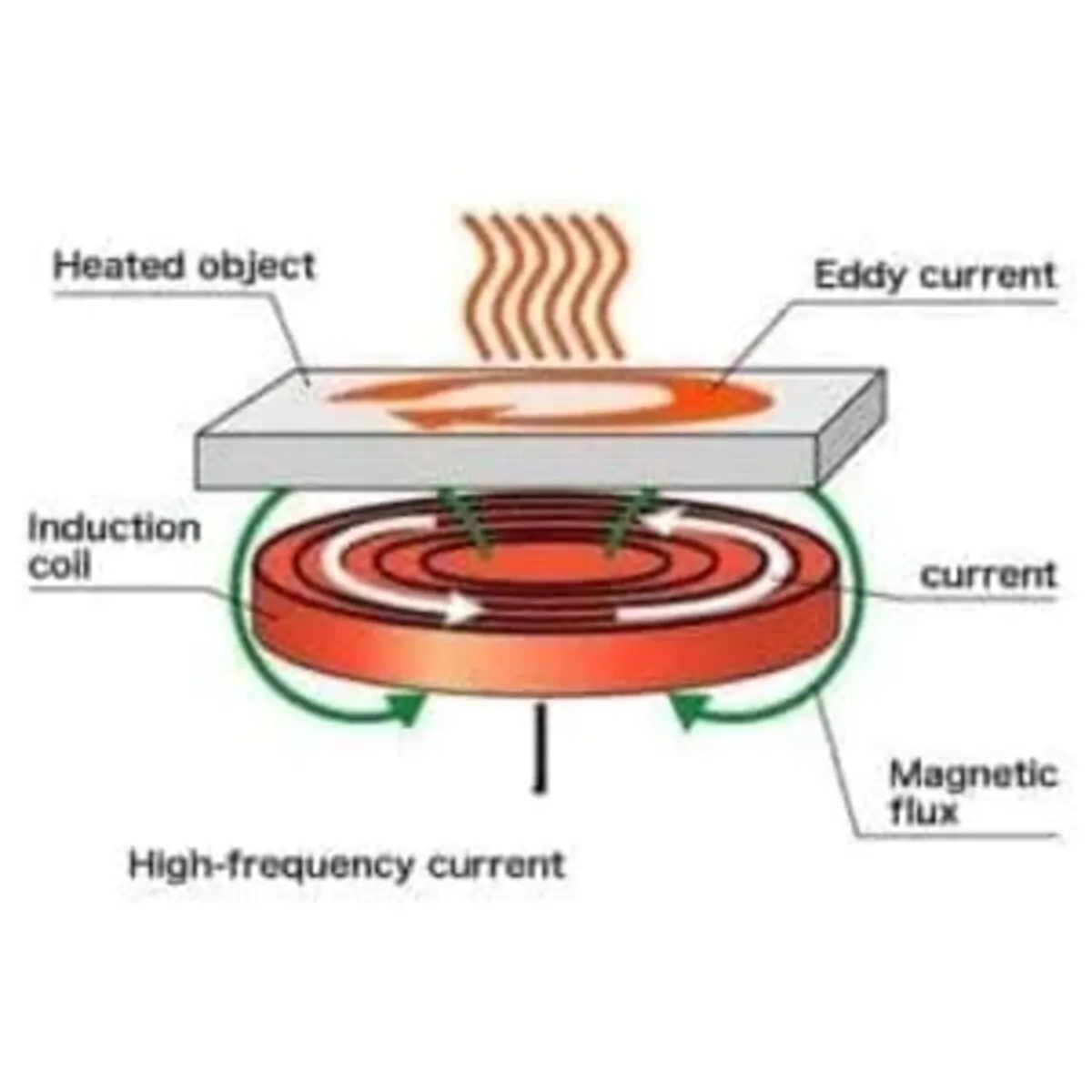

Induction heating operates on the principle of electromagnetic induction, where an alternating current (AC) passes through a coil, generating an oscillating magnetic field. This field induces eddy currents within the conductive material placed inside the coil, generating heat due to electrical resistance.

Types of Induction Heating Systems

Induction Furnaces

Induction furnaces melt metals in foundries and steel plants. They offer precise temperature control and energy efficiency, making them ideal for processing high-quality alloys.

Induction cooktops are a popular household application of induction heating. They provide fast and precise cooking with minimal energy loss. The cooktop itself remains cool to the touch, as heat is generated directly within the cookware.

Induction hardening systems are used to selectively harden specific areas of metal components, enhancing their wear resistance and durability without affecting the entire workpiece.

Advantages of Induction Heating

Energy Efficiency

Induction heating is highly efficient because it generates heat directly within the material, minimizing energy loss. This makes it more efficient than traditional heating methods, such as gas or resistance heating, where energy is lost in the process of transferring heat to the material.

Induction heating offers rapid heating rates, allowing for quick processing times and precise temperature control. This is especially important in manufacturing processes that require consistent and repeatable results.

Induction heating is a contactless process, reducing the risk of contamination and eliminating the need for open flames or hot surfaces. This enhances safety and cleanliness in industrial environments.

Applications of Induction Heating

Metal Melting and Forging

Induction heating is widely used in metalworking industries to melt metals and forge components. It offers precise control over the heating process, resulting in high-quality products.

Induction heating is ideal for heat treatment processes such as annealing, brazing, and tempering. It allows for selective heating of specific areas, optimizing material properties.

Induction cooktops have become popular in kitchens because they are efficient and safe. They provide fast and precise cooking, making them ideal for both home cooks and professional chefs.

Medical and Scientific Uses

Induction heating is used in the medical field for sterilization and hyperthermia treatment. In scientific research, it is used for experiments that require precise temperature control.

Induction Heating vs. Traditional Heating Methods

Efficiency Comparison

Induction heating systems are generally more efficient than traditional heating methods. They offer faster heat-up times and reduced energy consumption, which results in lower operating costs and improved productivity.

Induction heating is an environmentally friendly option. It produces no direct emissions and minimizes energy waste, contributing to a reduction in industrial processes’ carbon footprint.

While the initial investment for induction heating systems can be higher than traditional methods, the long-term savings in energy costs and increased efficiency often offset these costs.

Induction coils are typically made of copper tubing and are designed to generate a magnetic field that induces heat in the workpiece. The design and shape of the coil can be customized to suit specific applications.

The power supply provides the alternating current needed to create the magnetic field in the induction coil. It can be adjusted to control the heating rate and temperature.

Cooling systems are essential for maintaining the induction coil’s temperature and preventing overheating. Depending on the system’s design and application, they can include water cooling or air cooling.

Induction heating is most effective for conductive materials, such as metals. Non-conductive materials, like plastics and ceramics, cannot be heated directly using this method.

The initial cost of induction heating equipment can be higher than traditional systems, which may be a barrier for some businesses. However, the long-term savings and efficiency benefits often justify the investment.

Recent advancements in induction heating technology include the development of more efficient power supplies, improved coil designs, and enhanced control systems. These innovations continue to expand the applications and efficiency of induction heating.

As technology advances, new applications for induction heating are emerging, such as in the fields of renewable energy, electric vehicle manufacturing, and advanced material processing.

Induction heating is a powerful and efficient technology that offers numerous benefits across various industries. Its ability to provide precise, fast, and energy-efficient heating makes it a valuable tool in modern manufacturing and processing. As technology continues to evolve, induction heating is poised to play an even more significant role in the future of industry.

Induction heating is used for a wide range of applications, including metal melting, heat treatment, cooking, and medical procedures. It offers fast and precise heating with minimal energy loss.

Induction heating works by generating an electromagnetic field that induces eddy currents within a conductive material. These currents produce heat through electrical resistance, warming the material from within.

Yes, induction heating is highly energy-efficient because it generates heat directly within the material, minimizing energy loss. This makes it more efficient than traditional heating methods.

Induction heating is most effective for conductive materials, such as metals. Non-conductive materials, like plastics and ceramics, cannot be heated directly using this method.

Induction cooking offers several advantages, including fast and precise temperature control, energy efficiency, and safety. The cooktop remains cool to the touch, reducing the risk of burns and improving kitchen safety.

Read also: Käntäj: Unlocking the Future of Revolutionizing Translation Technology.

Overview of Kamagra Oral Jelly Kamagra Oral Jelly is a medication used to treat erectile…

Hey there, fellow game enthusiast! If you're diving into the world of OLXToto games, you're…

Imagine being whisked away on a thrilling adventure through snowy landscapes, all from the comfort…

In today’s dynamic market, Toronto stands at the forefront of premium kitchen design, and we…

Hey there! Let's dive into the wonderful world of log cabins. Whether you're dreaming of…

Dabbing culture has quickly become an exciting frontier for many concentrate enthusiasts. Among the various…