A U-Anchor is a sort of rooftop attachment system employed primarily in the construction sector. Think of it as a tiny but infamous piece of hardware that helps protect various materials and products to a roof. It’s just like the unsung hero that keeps almost everything in place, ensuring that your roof installations stay put, even in the facial skin of harsh weather conditions. Read the Best info about anchor products.

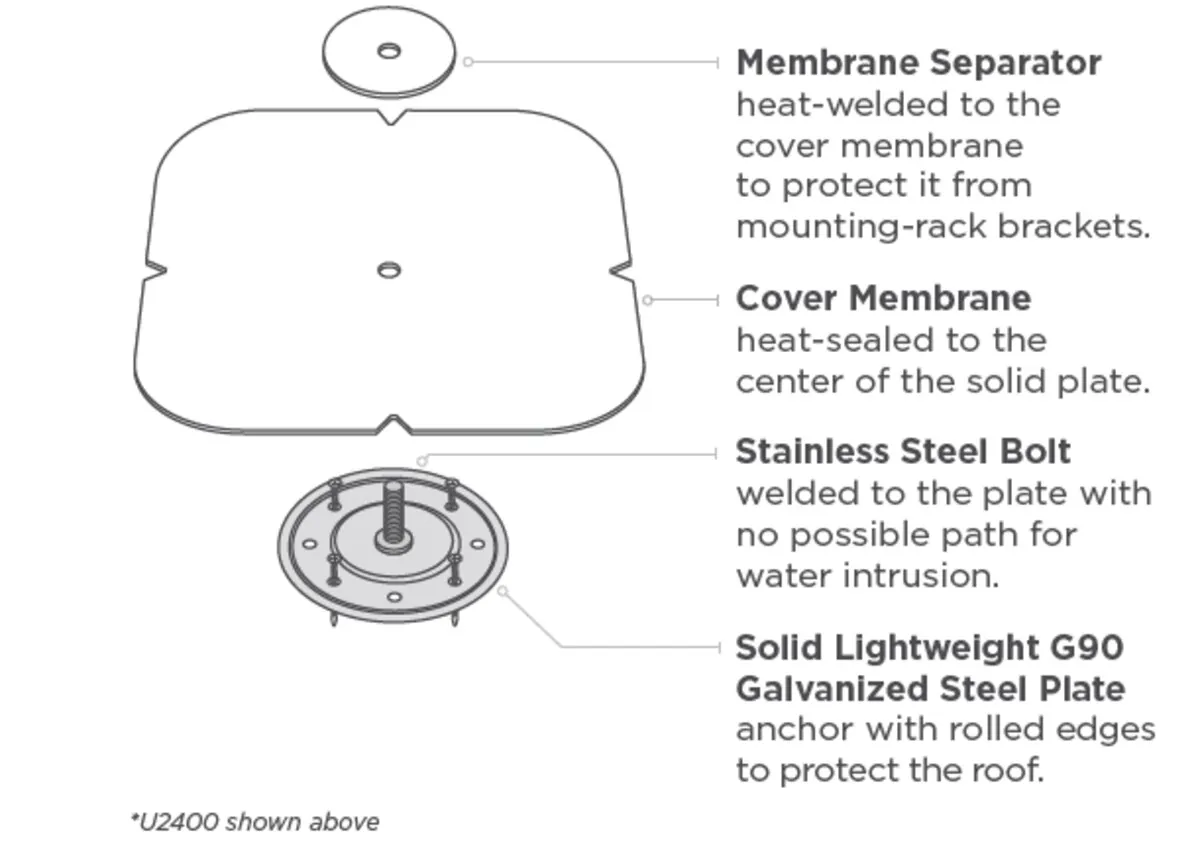

U-anchors are usually crafted from robust materials like stainless steel or galvanized iron, chosen for their strength and resistance to corrosion. The design of any U-anchor is deceptively simple, comprising a flat base and a U-shaped top that is the point of attachment. That design enables a lower profile installation that minimizes wind resistance and reduces the chance of roof damage.

The mechanism of a U-Anchor relies on distributing the stress across a more comprehensive location, which minimizes stress on the top structure. When a U-Anchor is installed, it uses anchoring screws or bolts that enter the roofing material, connecting the anchor firmly to the substructure. This ensures that the tools remain securely fastened, also under extreme weather conditions.

The concept of U-Anchors has evolved significantly over the years from basic anchoring systems found in construction. Advances in substance science and engineering have refined the design, making modern-day U-Anchors not only more durable but also more versatile. They have become vital in various industries, particularly with the rise of solar energy installations and high-tech HVAC devices.

U-Anchors boast a range of capabilities that make them indispensable inside construction and maintenance applications.

U-Anchors can be used for a wide selection of applications, from securing solar power systems and HVAC systems to helping anchor safety equipment and satellite dishes. Their style and design allow them to adapt to several roof types, whether ripped or pitched, and they can certainly accommodate various weights and sizes of equipment.

Manufactured from high-quality materials, U-Anchors can withstand the test of time and the elements. They are resistant to oxidation and corrosion, which means they will endure harsh weather conditions without degrading. This durability means long-term savings, as they demand minimal maintenance and replacement.

U-Anchors are known for their straightforward installation process, which ensures that they are a favorite among contractors and DIY enthusiasts alike. The method involves a few simple steps that may be completed with basic tools. This ease of installation not only saves time but also reduces labor fees, making U-Anchors a cost-effective option for various projects.

An often disregarded feature of U-Anchors is their exceptional weather resistance. These anchors are manufactured to hold steady under different environmental conditions, including large winds, heavy rain, and extreme temperatures. This reliability helps to ensure that rooftop installations remain protected regardless of the weather.

U-Anchors serve a multitude of uses across different sectors, featuring their versatility and consistency.

One of the most widespread uses for U-Anchors is protecting solar panels on rooftops. Solar power systems need to be securely fastened to ensure they can withstand strong winds and environmental factors. U-Anchors supply a reliable and sturdy option for this purpose.

In the context of electrical power, U-anchors play a crucial function in the stability and performance of solar panel arrays. They ensure the project panels are firmly attached, maximize vitality capture, and minimize thinking time due to maintenance or fixes. This reliability is essential regarding both residential and professional solar installations.

Environmental Gains

By facilitating the installation of solar power systems, U-Anchors contribute to the broader enviromentally friendly benefits of renewable energy. Secure solar energy installations mean more reliable energy generation, reducing reliability on fossil fuels and bringing down carbon footprints. As solar panel technology advances, U-Anchors will continue to be vital to sustainable building techniques.

Numerous case scientific studies highlight the effectiveness of U-Anchors inside solar panel installations. For instance, large-scale solar farms and city rooftop projects have efficiently utilized U-Anchors to ensure steadiness and performance. These studies illustrate how U-Anchors can conform to different environments and job scales, making them a versatile selection for solar projects.

HVAC systems tend to be another major application for U-Anchors. These systems are often heavy and require a safeguarded attachment to the roof to avoid movement or injury. U-anchors provide the necessary stability to keep HVAC units tightly in place.

In industrial and business-oriented settings, HVAC systems are generally critical for maintaining optimal interior environments. U-Anchors are essential for securing these systems, stopping movement that could disrupt procedures or cause damage. Their reliability ensures that HVAC models operate efficiently, maintaining comfy conditions for employees and clients.

In residential applications, U-Anchors assist in installing HVAC systems with minimal impact on the roof framework. Their ability to securely secure units without compromising roofing integrity makes them a favored choice for homeowners and contractors. This ensures that home HVAC systems are both efficient and durable.

The installation of HVAC systems provides unique challenges, such as body weight distribution and vibration management. U-Anchors address these difficulties by providing a stable foundation that minimizes vibrations and sells weight evenly. This decreases wear and tear on both the HEATING AND COOLING system and the roof, increasing the lifespan of each.

Safety is paramount, especially when working on roofs. U-Anchors can secure protection lines and other equipment, offering a safe working environment for structure workers and maintenance personnel.

U-anchors are generally integral to creating harmless working conditions on roofs. They serve as anchor details for safety lines and harnesses, ensuring that workers are secure while performing their duties. This reduces the unwelcome possibility of falls and other accidents, endorsing a safer work environment.

The application of U-Anchors in safety equipment PV panels helps companies comply with rigid safety regulations and criteria. These regulations often call for secure anchoring points intended for fall protection systems, generating U-Anchors, a necessary component designed for compliance. This not only protects personnel but also shields companies from potential legal liabilities.

Innovative developments in Safety Equipment

Recent improvements in safety equipment have extended the applications of U-Anchors. For example, they are now used in systems that monitor environmental conditions and alert workers to possible hazards. This integration with technology enhances safety measures, making U-Anchors even more valuable in building and maintenance projects.

Satellite Meals and Antennas

If you’ve ever endured a satellite dish setup, chances are a U-Anchor will be utilized to secure it. These kinds of anchors ensure that your satellite food remains stable and lined up, providing an uninterrupted signal party.

In the world of communication, U-anchors play a pivotal role simply by securing satellite dishes and antennas. This stability ensures consistent signal reception, which can be critical for both personal and business communications. Reliable connection systems depend on adequately fitted equipment, making U-Anchors a key ingredient.

Installation Challenges

The installation of dish dishes and antennas typically involves unique challenges, including precise alignment and in order to environmental elements. U-Anchors handle these challenges by providing a reliable base that maintains place and resists weather-related mobility. This ensures optimal effectiveness and longevity of the transmission systems.

As technological know-how advances, the demand for protected and reliable installation of satellite TV dishes and antennas will only increase. U-Anchors will continue to be crucial in meeting these requirements, adapting to new systems and installation techniques. This ongoing relevance underscores their particular importance in the communication market.

U-Anchors offer a range of benefits that will make them a preferred selection for construction and maintenance assignments.

Enhanced Stability

One of the biggest benefits of using U-Anchors is the boosted stability they provide. Whether it’s solar power systems, HVAC systems, or safety practices equipment, U-Anchors ensure that anything stays securely in place, lessening the risk of damage or crashes.

Long-Term Reliability

The reliability of U-Anchors ensures that installations remain secure after a while, reducing the need for frequent assessments and repairs. This security is crucial for maintaining the performance of installed devices, minimizing downtime, and ensuring consistent operation.

U-anchors provide solid protection against environmental factors, including wind, rain, and heat range fluctuations. This protection is crucial for maintaining the condition of rooftop installations, blocking damage, and extending the life expectancy of equipment.

Case Studies with Stability

Numerous case experiments demonstrate the enhanced stability furnished by U-Anchors in various applications. This kind of study highlights the anchors’ ability to withstand extreme ailments and maintain the secure addition of equipment, showcasing their consistency and effectiveness.

U-Anchors are designed for easy installation, which means you don’t have to be a professional contractor to use them. With a few basic equipment and a bit of know-how, you can install U-Anchors yourself, conserving time and money.

DIY-Friendly Approach

The U-Anchors’ user-friendly design makes them accessible for DIY lovers who wish to undertake rooftop assignments. Clear instructions and straightforward installation processes empower individuals to complete installations without professional guidance, offering cost savings and total personal satisfaction.

The ease of use of U-Anchor installation equals significant time savings for both DIY projects and skilled installations. This efficiency will allow projects to be completed faster, reducing labor costs and enabling quicker project completion.

Training and Resources

Quite a few manufacturers provide training and resources to assist with installing U-Anchors. These resources contain detailed guides, videos, and customer support, ensuring that users have the information they need to install U-Anchors correctly and effectively.

Speaking of saving money, U-Anchors may also be a cost-effective solution for solar power attachments. Their durability suggests you won’t have to replace these individuals frequently, and their ease of installation lessens labor costs.

Long-Term Enough cash

The durability and consistency of U-Anchors contribute to savings by minimizing the importance of replacements and repairs. That cost-effectiveness is particularly beneficial for large-scale projects where budget is critical.

U-Anchors are available in a range of value points, allowing customers to settle on options that fit their particular budget without compromising on quality. This flexibility helps ensure that U-Anchors can be used in a variety of assignments, from small residential installations to large commercial software.

Economic Impact

The widespread use of U-Anchors in design and maintenance contributes to the economic growth of related industries. By providing a cost-effective solution, U-Anchors helps expand the electrical power, communication, and safety industries, promoting job creation and industry development.

The actual versatility of U-Anchors should not be overstated. They can be used for many applications, making them a valuable improvement to any construction or repair toolkit.

Adaptability to Different Jobs

U-Anchors can adapt to distinct project requirements, whether it’s a minor residential installation or a significant industrial application. This versatility makes them a versatile choice for contractors, enabling them to use the same anchoring system throughout various projects.

The cross-industry applications of U-Anchors demonstrate their versatility. From renewable energy to safety gear, U-Anchors are used in varied sectors, highlighting their capability to meet different needs and challenges.

Future Potential

Because industries continue to evolve, the actual applications for U-Anchors will probably expand. Innovations in technologies and construction practices will create new opportunities for U-Anchors to be used in emerging areas, ensuring their continued importance and importance.

Installing a U-Anchor is a relatively straightforward procedure. Here’s a simple step-by-step instructions to help you out:

Step 1: Choose the Right Area

Determine where you need to set up the U-Anchor. Make sure the place is suitable for the type of attachment you’re securing.

When choosing an area, consider factors such as mass distribution, accessibility, and environmental exposure. These factors will undoubtedly influence the stability and efficiency of the U-Anchor installation.

Evaluate the roof structure to ensure it can support the weight and stress on the U-Anchor installation. This review may involve consulting with a structural engineer or utilizing specialized tools to assess the actual roof’s integrity.

Prepare the installation website by removing any particles or obstructions that could hinder the U-Anchor installation. This particular preparation is essential for ensuring a secure and steady attachment.

Clean the surface where the U-Anchor will be installed to ensure suitable adhesion.

Cleaning Techniques

Employ appropriate cleaning techniques and products to remove dirt, airborne dirt and dust, and moisture from the installation surface. This cleaning ensures that the U-Anchor adheres appropriately and maintains its stability over time.

Surface Inspection

Look at the surface for any damage or irregularities that could affect the installation. Address any issues, such as cracks or uneven areas, before proceeding with the set-up.

Consider the kind of adhesive or sealant that will be used in the installation procedure. Choosing the right product will ensure a solid bond between the U-Anchor and also the roof surface.

Place the U-Anchor in the desired location and mark the spots where you’ll need to drill holes.

Ensure that the U-Anchor is aligned appropriately and positioned according to the undertaking requirements. Proper alignment is necessary for maintaining the stability and effectiveness of the installation.

Paying Attention to Techniques

Use precise attention to techniques to indicate the going points. This precision might help prevent errors during the ongoing process and ensure a protective attachment.

Select the proper tools and equipment for positioning the particular U-Anchor. These may include computing tapes, markers, and position guides.

Using a drill, create openings in the marked spots.

Going Techniques

Employ proper going techniques to create clean in addition to accurate holes. This detail is essential for ensuring that the U-Anchor is often securely fastened and can support the expected load.

Safety Precautions

Take safety measures during the drilling process, including wearing protective eyewear in addition to gloves. These precautions might help prevent accidents and traumas.

Opt for the appropriate drill bit for any roofing material and U-Anchor specifications. Using the right tool bit will ensure a clear and precise hole, assisting a secure attachment.

Protected the U-Anchor in place, making use of screws or bolts, guaranteeing it is tightly fastened.

Buckling Techniques

Use proper buckling techniques to ensure that the U-Anchor is securely attached. This could involve using specific torque settings or fastening styles to distribute the load consistently.

After holdfast, check the alignment of the U-Anchor to ensure it is correctly inserted. This step is crucial for retaining the installation’s stability and effectiveness.

Final Adjustments

Produce any final adjustments to the U-Anchor installation, such as tensing screws or bolts. This kind of adjustments will ensure that the U-Anchor is secure and looking forward to use.

Give the U-Anchor a gentle whip to make sure it’s securely linked.

Stability Testing

Conduct steadiness testing by applying pressure to the U-Anchor and checking for almost any movement or shifting. This specific testing ensures that the setup is secure and can support the intended load.

Perform a visual assessment to identify any potential concerns, such as loose screws or perhaps misalignment. Address any difficulties before proceeding with the job.

Plan for continuous maintenance and inspections to ensure the long-term stability and success of the U-Anchor installation. Frequent checks will help identify and address any issues before they become significant problems.

There you have it! Your U-Anchor is installed and ready to provide a firm attachment for your rooftop tools.

When it comes to deciding on the best U-Anchor for your needs, there are a few considerations:

Load Capacity

Different U-Anchors have different load capacities, so it’s important to choose one that can support the weight of the equipment you aren’t securing. For example, the U-Anchor 2400 is known for its excessive load capacity, making it suitable for heavy-duty applications.

Understanding your project’s load specifications is essential for choosing the appropriate U-Anchor. Consider the equipment’s body weight, potential environmental stresses, and any additional loads that may be applied over time.

Compare the burden capacities of different U-Anchors to find out which one is best suited for your task. This comparison will help ensure that the chosen U-Anchor is designed for the intended load without compromising safety or balance.

In some instances, custom load solutions might be necessary to accommodate unique task requirements. Consult with manufacturers or even engineers to explore custom choices that meet specific masse needs.

Material

U-Anchors are manufactured from various materials, including stainless steel and galvanized steel. When choosing the material, consider the environmental conditions of your setup site. Stainless steel U-Anchors, for example, are highly resistant to corrosion and suitable for severe environments.

Material Properties

Be familiar with the properties of different materials employed in U-Anchors, such as strength, deterioration resistance, and thermal stableness. These properties will affect the U-Anchor’s U-Anchor’s performance and durability in specific situations.

Consider the environmental conditions of the installation site, such as humidity, temperature, and exposure to chemicals. Choose a material that can withstand these situations and maintain its integrity over time.

Assess the cost versus performance of various materials to determine the best option for your project. While some materials can be more expensive, their superior functionality and durability may justify typically the investment.

Compatibility

Make sure the U-Anchor you choose is compatible with the type of roof you have. Some U-Anchors are designed specifically for toned roofs, while others are suitable for frequency roofs.

Consider the type of roof on which the U-Anchor will be set up, such as flat, pitched, or even curved. This consideration will undoubtedly influence the design and installation requirements of the U-Anchor.

Make sure the U-Anchor is compatible with the roofing materials you are using to build your project. This compatibility will ensure a secure attachment and prevent problems with the roof structure.

Consult manufacturer recommendations along with guidelines to ensure compatibility using specific roof types and materials. These recommendations can provide valuable insights into the recommendations for U-Anchor installation.

Although U-Anchors might be small, they play a big role in ensuring the stability and security of rooftop installations. Their versatility, durability, and usefulness make them invaluable tools for a wide range of applications. Whether you’re securing solar panels, HVAC techniques, or safety equipment, U-Anchors provide a reliable and relatively inexpensive solution.

Because technology and construction routines continue to evolve, U-Anchors will be a critical component in a wide range of ovations. Their adaptability to new challenges and innovative developments ensures that they will continue to cater to various industries.

U-Anchors contribute to self-sufficient construction practices by allowing the installation of renewable energy systems and reducing the environmental impact of building projects. Their role in promoting durability underscores their importance throughout modern construction.

So, next time you’re working on the rooftop project, consider using U-Anchors to ensure everything stays safely in place. Their proven dependability and versatility make them an important part of any construction or maintenance toolkit. Happy setting up!

Overview of Kamagra Oral Jelly Kamagra Oral Jelly is a medication used to treat erectile…

Hey there, fellow game enthusiast! If you're diving into the world of OLXToto games, you're…

Imagine being whisked away on a thrilling adventure through snowy landscapes, all from the comfort…

In today’s dynamic market, Toronto stands at the forefront of premium kitchen design, and we…

Hey there! Let's dive into the wonderful world of log cabins. Whether you're dreaming of…

Dabbing culture has quickly become an exciting frontier for many concentrate enthusiasts. Among the various…